| The Hindenburg |

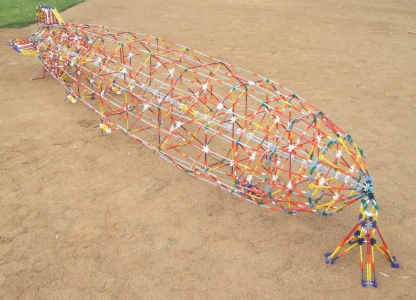

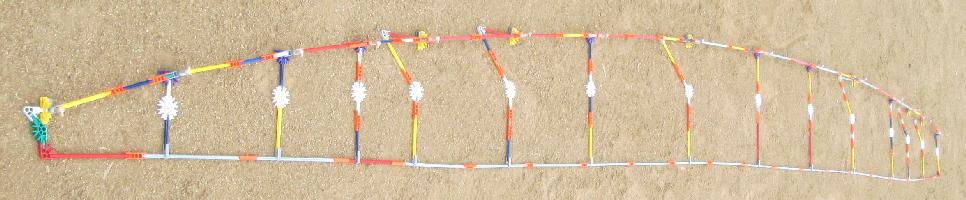

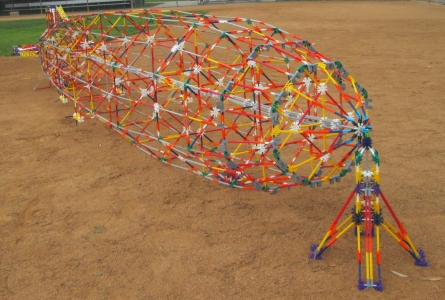

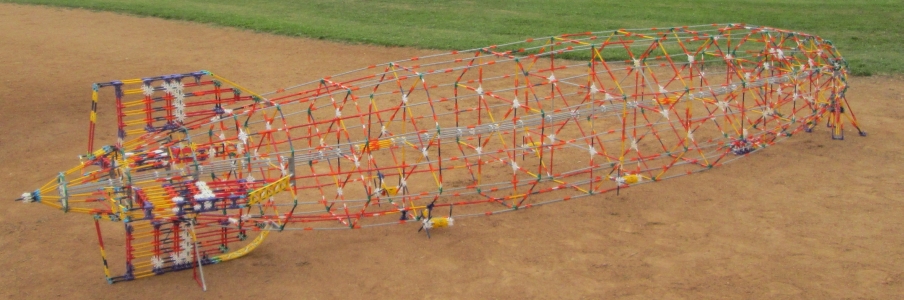

Here is a 1/54 scale model of the LZ 129 Hindenburg, the famous German zeppelin of the 1930's. This model of the airship is about 15 feet long and is made from nearly 5,000 K'NEX parts. Read on for more information on how this scale model was built. Click on the photos for larger versions.

|

|

TABLE 1

Horizontal Vertical Location

pixel pixel

coordinate coordinate

0 0 Extrapolated stern endpoint

75 40

195 98

314 137

434 172 Base of fin (excluding rudder)

531 198

628 222

726 245 Frame 33.5

823 266

920 286

1017 304

1126 321 Fin leading edge join

1234 337

1342 352 Frame 62 (1st gas vent)

1451 365

1559 376

1667 387

1776 396

1788 397

1884 403

1992 411 Frame 92 (2nd gas vent)

2101 417

2209 424

2317 429

2436 434

2555 437

2674 440 Frame 123.5 (3rd gas vent)

2793 443

2913 446

3031 446

3151 446

3270 446

3388 446 Frame 156.5 (4th gas vent)

3508 444

3603 442

3627 441

3746 437

3854 432

3963 427

4070 421 Frame 188 (5th gas vent)

4179 414

4288 405

4395 394

4504 380

4612 363

4720 342 Frame 218 (6th gas vent)

4829 317

4937 285

5045 242

5132 199

5219 140

5294 64 Frame 244.5

5329 18

5344 0 Nosecone

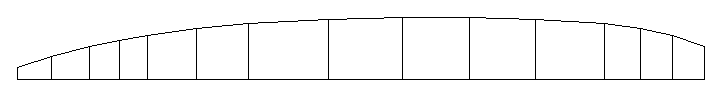

In this scale, the airship has a length of 5344 pixels and a maximum diameter of 2 x 446 = 892 pixels, and so

it is almost exactly 6 times as long as its maximum diameter. These proportions are corroborated by the

dimensions of the actual Hindenburg airship: length 804 feet and diameter 135 feet. A diagram of these data

points serves to confirm the general shape of the airship profile (stern on the left):

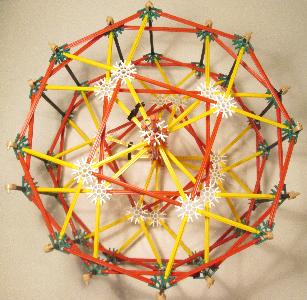

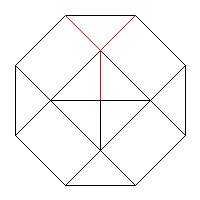

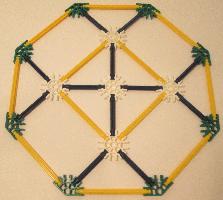

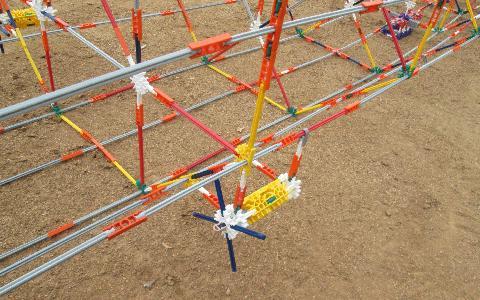

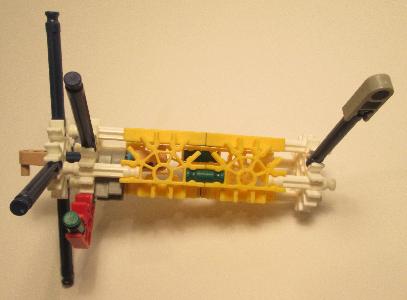

The cross-section of the actual zeppelin was a 36-sided regular polygon, but there are only a few possibilities for that shape in K'NEX without extensive bending of parts, particularly at smaller diameters. So we first tried a simpler 16-sided regular polygon (hexadecagon), and one way of creating it is to use two nested octagons with an offset of 22.5 degrees held in place with a ball-and-socket joint from one of the K'NEX figures:

|

|

|

|

Each side of the octagon is equivalent to a number g of green rods plus a number W of white rods, all linked by connectors (usually orange ones). For example, if the side of the octagon is a red rod connected with a yellow rod, the overall side length can be represented as g = 4 & W = 2. This is because a red rod is equivalent to four connected green rods, and a yellow rod is equivalent to two connected white rods. The octagon side must use an even value for g so that diagonal Y-shaped bracing can be provided as shown in red in the diagram above. The overall length S (in millimeters) of the octagon side between the centers of the holes of the connectors used for the vertices is

S = 37.6 g + 53.2 W mmusing known dimensions for the K'NEX parts.

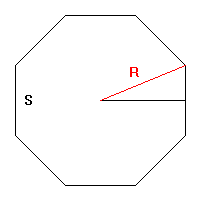

What is the radius R (half the diameter) of an octagon created in this way? It is the distance from its center to one of its vertices, as shown in red in the diagram below:

Since the interior angle of an octagon is 360/8 = 45 degrees, a right triangle can be visualized that has a central angle of 22.5 degrees and a height equal to one-half the octagon side S. Using a well-known formula from trigonometry, we have

R sin 22.5° = S/2or

R = 1.3066 STo provide enough detail for the airship appendages (engines, control car, etc.), the overall length of the model is 15 feet, or about a 1/54 scale with respect to the actual zeppelin. At the 6:1 aspect ratio described above, that scale results in a maximum diameter of 30 inches, or a maximum radius of 381 mm (at 25.4 mm per inch). Using the formula above and the previously-described requirement that the number g of green rods be even, we have 15 possibilities for the size of the vertical frames:

TABLE 2 ----Frame side---- Radius 0 g 1 W 53 mm 70 mm 2 g 0 W 75 mm 98 mm 0 g 2 W 106 mm 139 mm 2 g 1 W 128 mm 168 mm 4 g 0 W 150 mm 197 mm 0 g 3 W 159 mm 209 mm 2 g 2 W 181 mm 237 mm 4 g 1 W 203 mm 266 mm 0 g 4 W 212 mm 278 mm 6 g 0 W 225 mm 295 mm 2 g 3 W 234 mm 307 mm 4 g 2 W 256 mm 336 mm 0 g 5 W 266 mm 348 mm 6 g 1 W 278 mm 364 mm 2 g 4 W 288 mm 376 mm

The first pass of the optimization process produces the following raw data, ordered from stern to bow:

TABLE 3 Frame Slant distance Error side to next frame 53 mm 78 mm -3 mm 75 mm 140 mm 3 mm 106 mm 111 mm 2 mm 128 mm 123 mm 5 mm 150 mm 53 mm 0 mm 159 mm 135 mm -6 mm 181 mm 167 mm 0 mm 203 mm 80 mm -5 mm 212 mm 121 mm 7 mm 225 mm 99 mm 7 mm 234 mm 312 mm -2 mm 256 mm 179 mm 2 mm 266 mm 303 mm -1 mm 278 mm 447 mm 0 mm 288 mm 400 mm 0 mm 288 mm 397 mm -2 mm 278 mm 283 mm -3 mm 266 mm 133 mm -4 mm 256 mm 216 mm -3 mm 234 mm 64 mm -10 mm 225 mm 81 mm -5 mm 212 mm 52 mm 0 mm 203 mm 99 mm 7 mm 181 mm 76 mm 0 mm 159 mm 29 mm 8 mm 150 mm 65 mm 9 mm 128 mm 52 mm 1 mm 106 mm 65 mm 10 mm 75 mm 39 mm -1 mm 53 mmTable 3 lists the slant distances between frames if all of the possible K'NEX frame sizes were used for both bow and stern tapers of the airship. It also shows the errors resulting from the approximations of the actual slant distances with K'NEX parts. To avoid overcrowded frames and retain an accurate airship shape, the goal is to find optimal frames that are at least 8 inches (203 mm) apart, about the length of a grey K'NEX rod. This has the advantage of reducing error in the slant distances since they will be computed over a longer distance. Also, we want to ensure that frames close to the leading and trailing edges of the tail fins are included so that we have good attachment points. Those fin-attachment frames are:

TABLE 4 Horizontal Vertical Vertical K'NEX K'NEX Location coordinate coordinate distance radius side 434 px 172 px 145 mm 139 mm 106 mm Base of fin (excluding rudder) 1126 px 321 px 271 mm 266 mm 203 mm Fin leading edge joinThere may be additional, intermediate frames that can also be used to anchor the fins.

Based on a manual analysis of the raw data in Table 3, optimal selections are grouped together to produce the following smaller list of frames and more-accurate slant distances:

TABLE 5 Frame ---Slant distance--- Error side to next frame 53 mm 218 mm 3 g 2 W 1 mm 106 mm 233 mm 2 g 3 W 1 mm Fin attachment point 150 mm 189 mm 5 g 0 W -1 mm 181 mm 167 mm 3 g 1 W 0 mm 203 mm 300 mm 8 g 0 W 0 mm Fin attachment point 234 mm 312 mm 4 g 3 W -2 mm 256 mm 482 mm 10 g 2 W 0 mm 278 mm 447 mm 2 g 7 W 0 mm 288 mm 400 mm 5 g 4 W 0 mm 288 mm 397 mm 2 g 6 W -2 mm 278 mm 416 mm 4 g 5 W 0 mm 256 mm 216 mm 0 g 4 W -3 mm 234 mm 197 mm 1 g 3 W 0 mm 203 mm 204 mm 4 g 1 W 0 mm 150 mm 220 mm 3 g 2 W -1 mmTable 5 coincidentally contains 15 optimal frames, but is not related to the 15 possible K'NEX frame sizes in Table 2 since some frame sizes are reused at each end of the airship, and other sizes are not used at all. A diagram of these data points serves to confirm the general shape of the airship (the nose and stern cones will be fitted manually):

TABLE 6 Frame side Diagonal bracing Slant distance to next frame Radius Slant Deviation from 180° W g Y+B+g 70 mm 218 mm * Y B Y+B+W 139 mm 233 mm 4 * R Y R+g 197 mm 189 mm 2 * Y+B B+W B+W+g 237 mm 167 mm 2 R+W Y+g 2R 266 mm 300 mm 2 Y+B+W B+W+g R+Y+W 307 mm 312 mm 3 R+Y Y+B 2R+Y+B 336 mm 482 mm 2 R+B+W Y+W+g G+Y+B+W 364 mm 447 mm 2 G+B R+W G+R+g 376 mm 400 mm 2 G+B R+W G+Y+B 376 mm 397 mm 2 R+B+W Y+W+g G+R+W 364 mm 416 mm 2 R+Y Y+B G 336 mm 216 mm 4 Y+B+W B+W+g Y+W+g 307 mm 197 mm 4 R+W Y+g R+W 266 mm 204 mm 8 * R Y Y+B+g 197 mm 220 mm *where the following symbols are used:

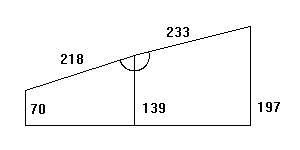

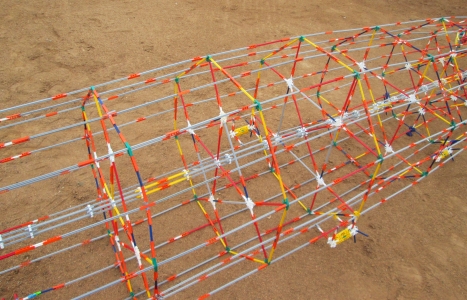

g: Green rod W: White rod B: Blue rod Y: Yellow rod R: Red rod G: Grey rod +: Orange connectorThe rods in the diagonal bracing are one K'NEX size down from those in the frame side. Table 6 also includes calculations for how closely to a straight angle (180°) the longitudinal stringers intersect the perimeters of the vertical frames. For example, in the side-view profile below, the frame with one yellow rod for each side (radius 139 mm) has the following dimensions (mm), with respect to its two adjacent frames:

These dimensions result in a calculation of 176° for the indicated angle, or about 4° off of a straight angle, using the inverse-cosine trigonometric function:

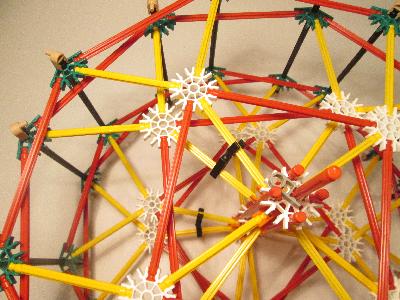

139 - 70 139 - 197 Arccos ---------- + Arccos ----------- = 176° 218 233As described above, the zeppelin model has 16 stringers connected to the perimeter of each octagonal frame. For the best uniform appearance, these stringers pass through the corners of the octagons, as well as through the midpoints of their sides. The corner stringers pass through the central hole of each green connector used for the frame corner. In practice, depending on the stringer lengths involved, a deviation of more than about 4° or so from a straight 180° intersection angle results in too much tilting of the green connector and associated distortion of the vertical frame and/or stringers. Therefore, the stringer connections at the frames indicated with asterisks in Table 6 (along with the nose and tail cones) have pivoting attachments to allow for steeper angles between frames.

At those locations needing flexible angles between consecutive frames, stringers are attached to the frame perimeter with pivots. These pivots can be realized with dark-grey K'NEX connectors that attach to the end of stringer rods and swing freely on the octagon sides. Multiple pivots may be needed on each side, depending on the number of fore and aft stringer connections.

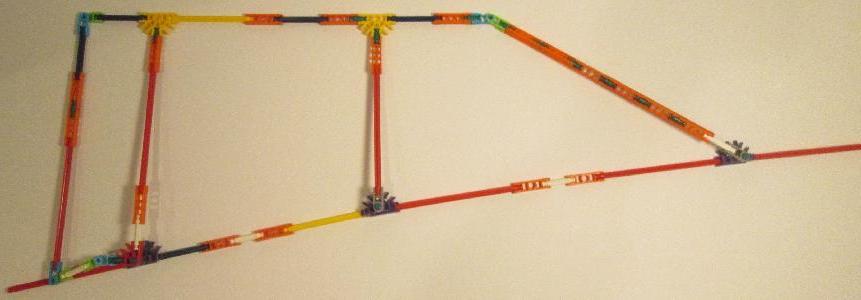

In Table 6, frames not terminated with an asterisk at the end of the line are located where there isn't much tapering in the airship envelope, and so stringer pivots do not not need to be used on them. In this case, the stringer rods between the frames can be rigidly attached to connectors on the frame structure. This design is shown in the right-hand profile photo below, while the left-hand photo shows the pivots used when stringers make a slight corner at the frame:

|

|

Starting at the stern and moving forward, a frame construction plan is as follows:

TABLE 7 Frame side Implementation Pattern Photo Notes W W XX| Frame style A Y W+W CX|(YYYY)|XC Frame style B Y (at fin) Y CXFCCXCCFXC Frame style Bf R B+B CC|X|CC(YYYY)CC|X|CC Frame style C Start of stringers at octagon corners R (at fin) R CCXCC|FCCXCCF|CCXCC Frame style Cf Start of stringers at octagon corners Y+B g+W+W+g (OOOO)..:(WWWW):..(OOOO) Frame style D R+W B+W+B (BBBB)(OOOO)|OC(OOOO)(BBBB) Frame style E R+W (at fin) R+W CCCCCCCCCCFCCOCCFC(OOOO):.. Frame style Ef Y+B+W g+W+W+W+g (OOOO)..:(OOOO)|OC(OOOO):..(OOOO) Frame style F R+Y W+B+B+W ..:(OOOO)(BBBB)(OOOO)(BBBB)(OOOO):.. Frame style G Stringer passthrough at midpoint R+B+W g+B+W+B+g (OOOO)(BBBB)(OOOO)|OC(OOOO)(BBBB)(OOOO) Frame style H G+B Y+g+g+Y (YYYYYYYYY)(OOOO)(OOOO)(OOOO)(YYYYYYYYY) Frame style I Stringer passthrough at midpoint G+B Y+g+g+Y (YYYYYYYYY)(OOOO)(OOOO)(OOOO)(YYYYYYYYY) Frame style I Stringer passthrough at midpoint R+B+W g+B+W+B+g (OOOO)(BBBB)(OOOO)|OC(OOOO)(BBBB)(OOOO) Frame style H R+Y W+B+B+W ..:(OOOO)(BBBB)(WWWW)(BBBB)(OOOO):.. Frame style J Y+B+W g+W+W+W+g (OOOO)..:(OOOO)|OC(OOOO):..(OOOO) Frame style F R+W B+W+B CCCC|X|(OOOO)|XC(OOOO)|X|CCCC Frame style K End of stringers at octagon corners R B+B CC|X|CC(YYYY)CC|X|CC Frame style Lwhere the following notation is used:

g: Green rod W: White rod (inline space for 2.5 connectors) B: Blue rod (inline space for 6 connectors) Y: Yellow rod (inline space for 11 connectors) R: Red rod (inline space for 18 connectors) G: Grey rod (inline space for 28 connectors) +: Orange connector inline (occupies space of 6 connectors) X: Dark-grey connector at end of stringer O: Orange connector at end of stringers F: Fin connector C: Dark-grey connector as spacer (rotating freely) |: Light blue washer (1/2 connector thickness) .: Connector space on white rod :: Washer space on white rod (OOOO): Orange connector (connected inline with rods) (YYYY): Yellow connector (WWWW): White connector (BBBB): Blue rod (YYYYYYYYY): Yellow rod

With the aforementioned ratio of 1.186 pixels per mm, we can determine the K'NEX parts to approximate the fin profile:

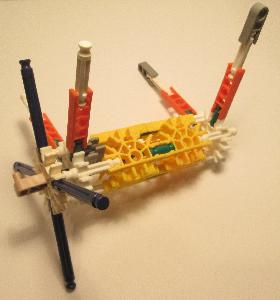

Based on the technical drawings referenced above, the maximum thickness of each fin is 89 pixels, or about 75 mm at the scale of the model. The average fin thickness is somewhere around half that, equivalent to two connectors attached by a single green rod. Therefore, two sides of each three-dimensional fin are created and connected together with a green rod. A total of three connections of each fin to the main body of the airship model are determined by fitting. Technically, the lower fin of the actual airship is slightly different from the other three in that it tapers upward slightly towards the stern. However, this minor change is not implemented in the K'NEX model, and all four of its fins are identical.

|

|

The following pictures highlight the connections of the fin to the airship envelope:

|

|

4g + W + (2g + 4W)/2 = 5g + 3W = 348 mm.This size provides a number of options for a realistic mast design. In particular, outer supporting struts at a steeper angle of about 60 degrees are possible, similar to the actual Lakehurst mooring mast. We ended up extending the height of the mooring mast by one additional green rod to facilitate the mast design and allow clearance for the control car.

|

|

|

|

|

|

|

And here are some close-ups of the control car:

|

|

A couple of small artificial props can be seen in some of the photos; these are added to prevent the model from sagging or tipping since its central axis is somewhat flexible.

|

|

|

|

|

A modification of the central axial tube can be used to allow the airship model to be easily disassembled into sections:

If the K'NEX airship were the actual size of the Hindenburg zeppelin, our 1/54 model would be the size of a yellow rod in comparison (outlined in red below):

HINDENBURG AIRSHIP PART COUNTS Orange Connector 1007 Green Rod 622 Dark Grey Connector 500 White Rod 468 Blue Rod 399 Yellow Rod 289 Grey Rod 243 Red Rod 227 Purple Connector 204 White Connector 184 Washer 169 Green Connector 144 Yellow Connector 140 Red Connector 59 Hinge 50 Brown Connector 29 Blue Connector 16 Light Grey Connector 2 Total 4752